Manufacturing Infrastructure & Machinery

At Shivaya Flexipack, our manufacturing setup is equipped with modern, high-speed machinery to ensure consistent quality, precise printing, strong lamination, and accurate slitting, meeting both domestic and export

packaging standards.

8 Colour Rotogravure Printing Machine

Designed for high-definition printing and colour

consistency, this machine delivers excellent print

quality across a wide range of flexible packaging

substrates.

Key Capabilities :

- Up to 150 meters/minute printing speed

- 8-colour high-precision rotogravure printing

- Web width up to 1000 mm

- Suitable for PET, BOPP, LDPE & laminated films

- Advanced drying system for solvent-based inks

- Accurate registration and stable web handling

Solventless Lamination Machine

Our solventless lamination facility enables eco-friendly,

high-strength bonding for multilayer laminates with

excellent clarity and performance.

Key Capabilities :

- High-speed lamination up to 350 meters/minute

- Working width up to 1000 mm

- Precise adhesive coating with auto mixing & dosing

- Water-heated rollers for controlled lamination

- Suitable for PET, BOPP, MET films, LDPE, LLDPE

- Strong bond strength for food & non-food

applications

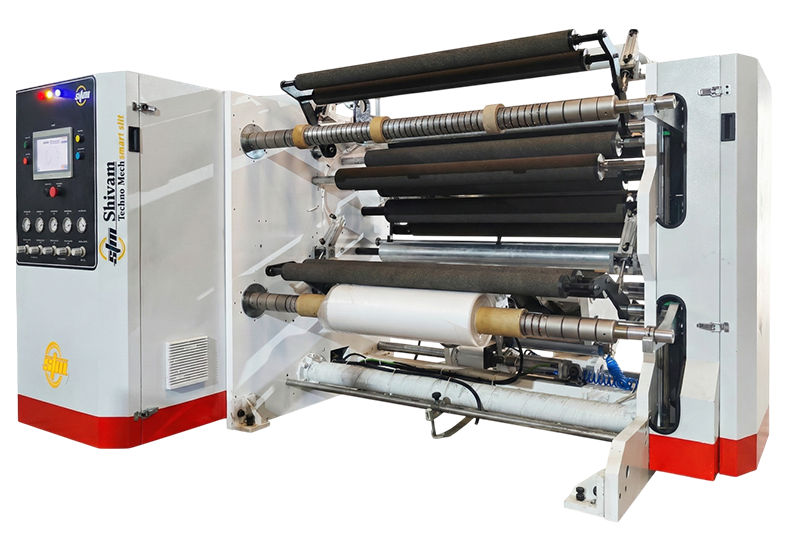

Slitting Machine

Ensures accurate slitting and rewinding with uniform

tension control for smooth downstream packaging

operations.

Key Capabilities :

- Operating speed up to 200 meters/minute

- Web width up to 1200 mm

- Automatic tension control with load cell feedback

- Shaftless unwinding & air-shaft rewinding

- Razor blade trimming system with trim blower

- Suitable for BOPP, PET, LDPE & laminated films