Used to simulate actual sealing conditions, this equipment helps determine optimum sealing temperature, pressure, and dwell time. It enables evaluation of seal strength, seal integrity, and peel behavior, ensuring reliable sealing performance for various packaging applications.

Used to simulate actual sealing conditions, this equipment helps determine optimum sealing temperature, pressure, and dwell time. It enables evaluation of seal strength, seal integrity, and peel behavior, ensuring reliable sealing performance for various packaging applications.

Employed for adhesive curing studies, thermal stability assessment, and accelerated aging tests. Controlled temperature exposure helps verify lamination curing, heat resistance, and material behavior under elevated temperature conditions.

Employed for adhesive curing studies, thermal stability assessment, and accelerated aging tests. Controlled temperature exposure helps verify lamination curing, heat resistance, and material behavior under elevated temperature conditions.

Measures light transmission and opacity levels of films and laminates. This ensures uniform appearance, print clarity, and compliance with product protection requirements, especially for light-sensitive food and pharmaceutical products.

Measures light transmission and opacity levels of films and laminates. This ensures uniform appearance, print clarity, and compliance with product protection requirements, especially for light-sensitive food and pharmaceutical products.

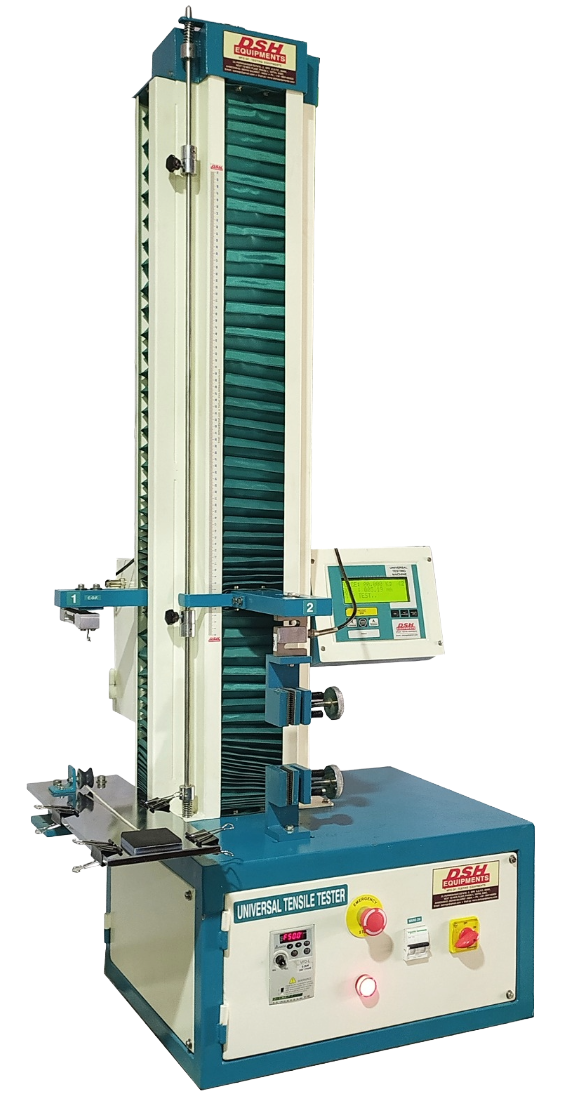

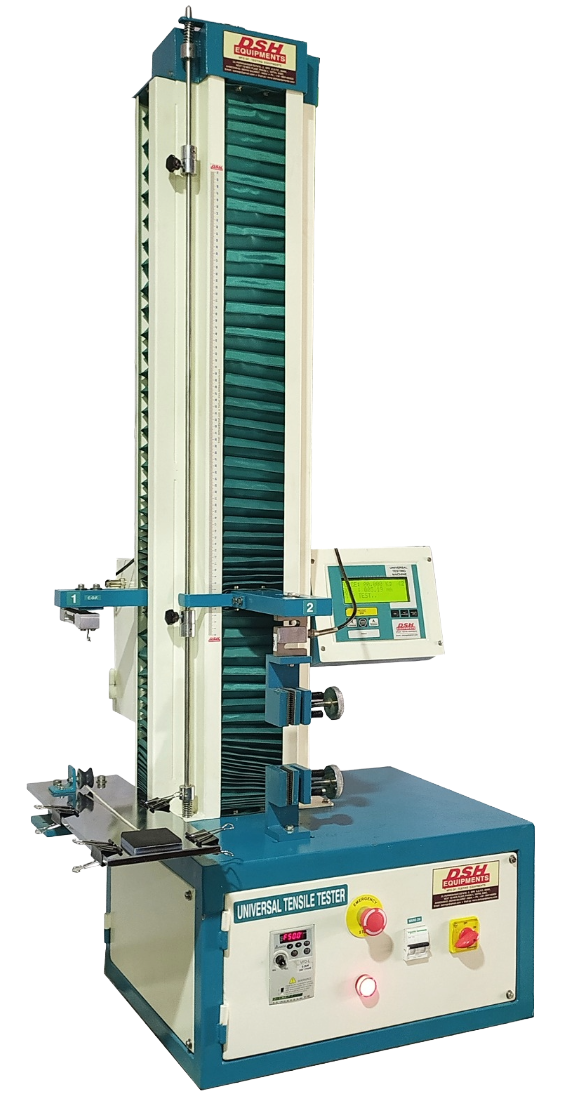

Used to evaluate mechanical properties such as tensile strength, elongation at break, and load-bearing capacity. These parameters are critical to ensure durability, machinability, and performance during filling, sealing, handling, and transportation.

Used to evaluate mechanical properties such as tensile strength, elongation at break, and load-bearing capacity. These parameters are critical to ensure durability, machinability, and performance during filling, sealing, handling, and transportation.

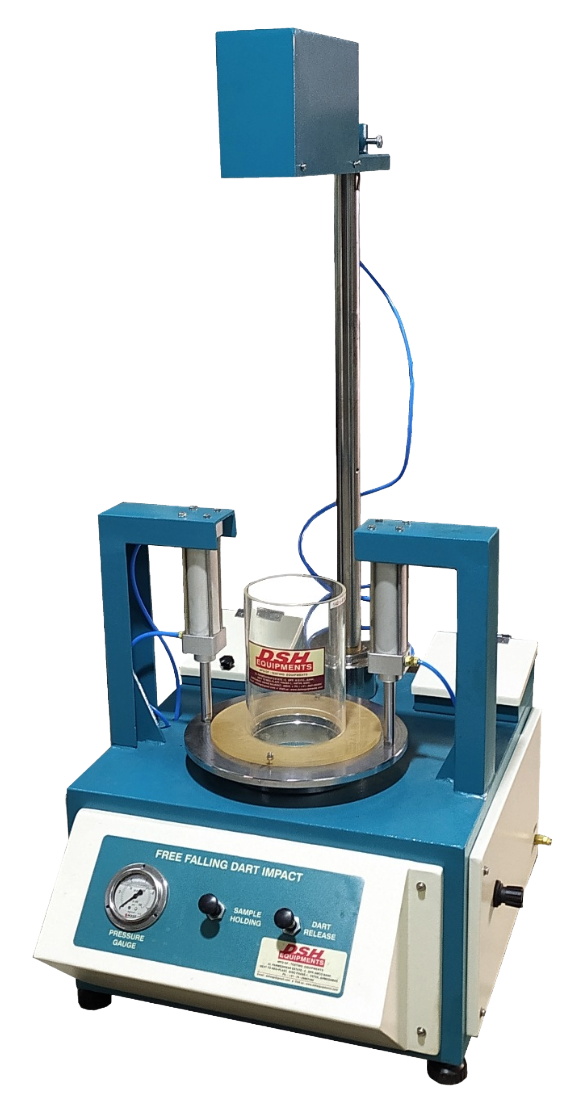

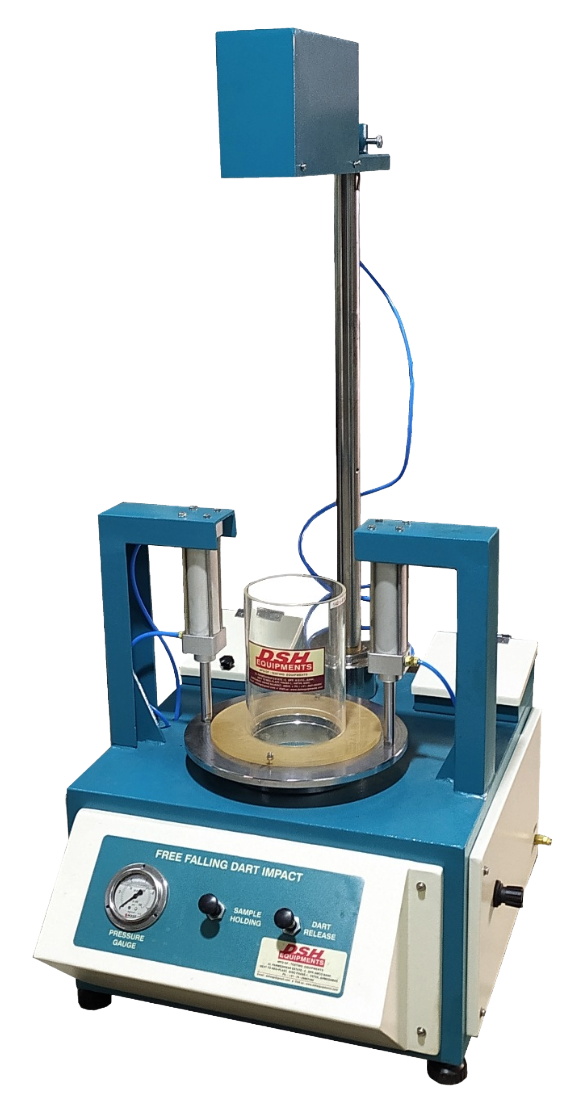

Assesses impact resistance and puncture strength of flexible packaging materials. This test ensures that the packaging can withstand sudden impacts and handling stresses without failure during logistics and end use.

Assesses impact resistance and puncture strength of flexible packaging materials. This test ensures that the packaging can withstand sudden impacts and handling stresses without failure during logistics and end use.

Provides accurate measurement of GSM and material consistency across film and laminated structures. Regular GSM monitoring helps maintain thickness uniformity, cost control, and adherence to specified product standards.

Provides accurate measurement of GSM and material consistency across film and laminated structures. Regular GSM monitoring helps maintain thickness uniformity, cost control, and adherence to specified product standards.

All tests are conducted as per defined internal procedures and relevant industry standards. Results are recorded, analyzed, and used for process control, continuous improvement, and customer assurance. This robust quality framework enables us to deliver flexible packaging solutions with consistent performance, reliability, and safety.

WhatsApp us